❤ Small production on demand❤ Certified & recycled precious metals❤ Made in Pforzheim, Germany

Menu

Menu

Meet our founder Alexandra Schwarzwald, the creative mind behind Fine Principles. With a keen eye for detail and a visual vocabulary that speaks the language of geometry and grids, Alexandra uses the potential of folding techniques and creates multi—faceted jewellery according to a meticulous principle of order.

But let’s start from the beginning. After completing her BA in Communication Design in 2015, Alexandra discovered the passion for jewellery making. She shifted her focus from graphics to object design and started crafting wax models by hand. At the start of her journey, she was already taking a systematic approach to her studies. So, she delved into facets and their impact on various dimensions.

Alexandra was on a mission to discover new design possibilities, and she decided to dig into the world of digital folding. With a newfound excitement for 3D modelling, she decided to shift her focus from analogue wax work to digital, where she recognized a great potential in this field.

In August 2021, she took a creative break and explored shapes resulting from a variety of folding grids. Months of testing and prototyping later, her first collection, ‘Series XF’ was finally ready to be shown to the world. The reveal happened at the BLICKFANG design fair in Hamburg in October 2022, where the jewellery was presented to the public eye.

Well, let us break it down for you in simple terms. An alloy is a composition of two chemical elements, one of which is always a metal. This blend results in a material with improved properties, making it more durable than its individual components.

As pure precious metals are too soft for jewellery processing, additional metals such as copper, tin, bronze, or brass are added to the precious metals. These make the piece of jewellery harder and more resistant to corrosion.

Depending on the mixing ratio, different shades such as yellow, red, rose or white gold can also be achieved by adding silver, or copper. Less well-known gold alloys are green, blue, or black gold.

Alloys also play an important role in the processing or function of the piece of jewellery. Although 18k gold alloys are of higher quality, they are also softer and not really suitable for work-intensive activities, especially in the case of rings. Therefore, 14k gold alloys are preferred for everyday use in order to guarantee longevity.

Bauer Walser is one of three refineries near Pforzheim from which our partner foundry Kalman Hafner sources certified and recycled materials. The company Bauer Walser for precious metals and semi-finished products is a member of the RJC (Responsible Jewellery Council) and holds RJC CoC (Custody of Chain) and RJC CoP (Code of Practices) certifications. This ensures transparency throughout the entire supply chain process to guarantee our jewellery is responsibly sourced.

Please do not get confused — bronze is not a precious metal. It is merely an alloy consisting primarily of copper and tin, to which other metals (including aluminium, manganese, nickel, or zinc) and sometimes non-metals are often added.

‘Carat’ (or metric carat = ct) is used as a unit of measurement and indicates the mass of gemstones.

Originally, carat weighed as much as a dried carob seed, in the Middle Ages as much as three grains of barley or four grains of wheat. In order to standardise the differences across national borders, the values were adjusted at the beginning of the 20th century. Since 1907, exactly 2 milligrams (0.2 grams) has equated to one metric carat.

The caster we work with purchases recycled precious metals from local suppliers near Pforzheim with RJC (Responsible Jewellery Council) certification. They follow the standards of RJC CoC (Chain of Custody) and RJC CoP (Code of Practices). In other words — RJC is the world’s leading sustainability organisation in the jewellery industry.

Both, the caster and goldsmith comply with REACH regulations throughout the entire supply chain. REACH stands for Registration, Evaluation, Authorization, and Restriction of Chemicals and is a regulation of the European Union (EC) No 1907/2006.

Additionally, the caster receives ‘fair gold’ from Fairever, which is a certified supplier of Fairtrade gold and silver and an authorised supplier of Fairmined gold and silver.

Matched by ’logic & beauty‘ — these are the two components that make up Alexandra’s jewellery. They follow mathematical and design principles to support the clearly structured concept and allow scope for further series.

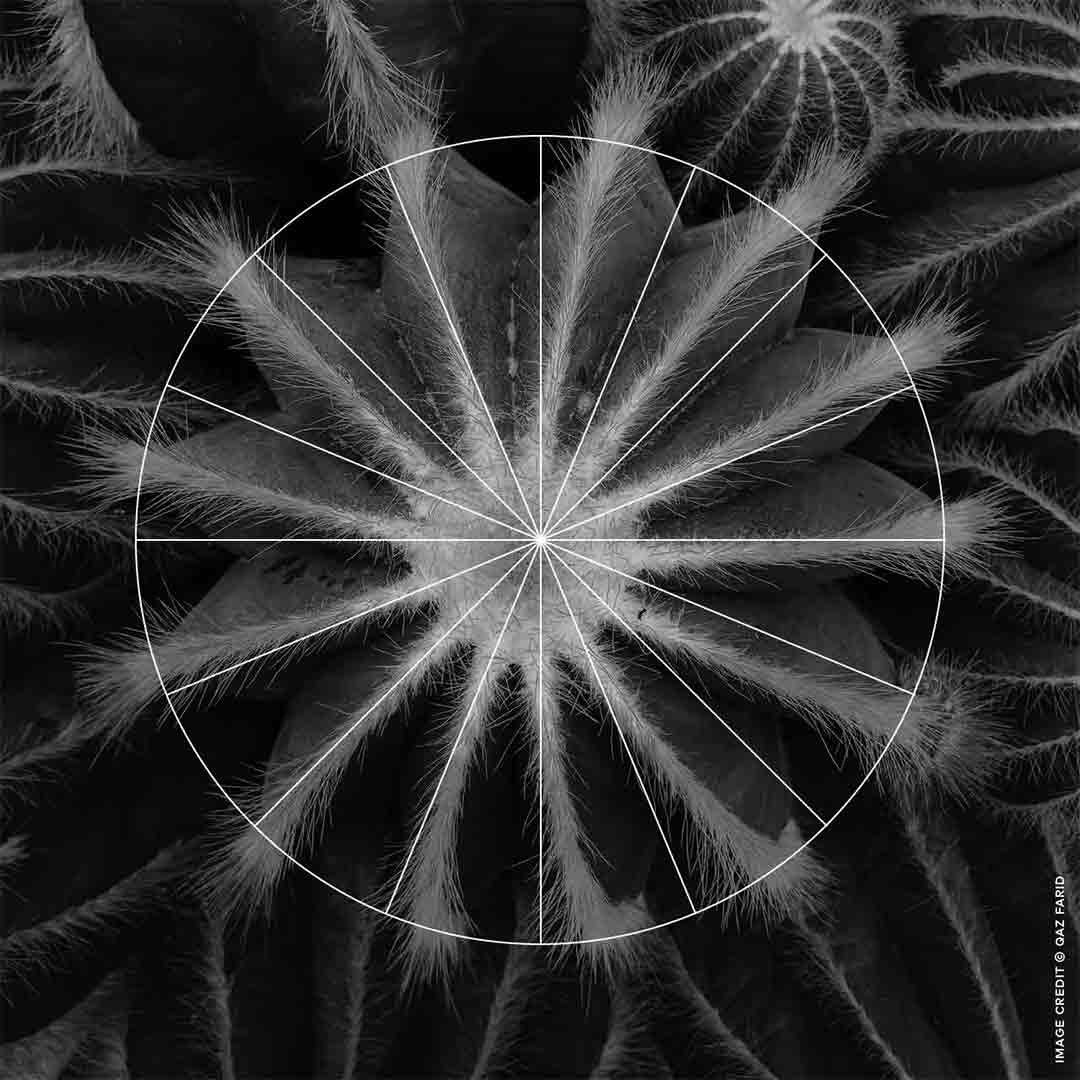

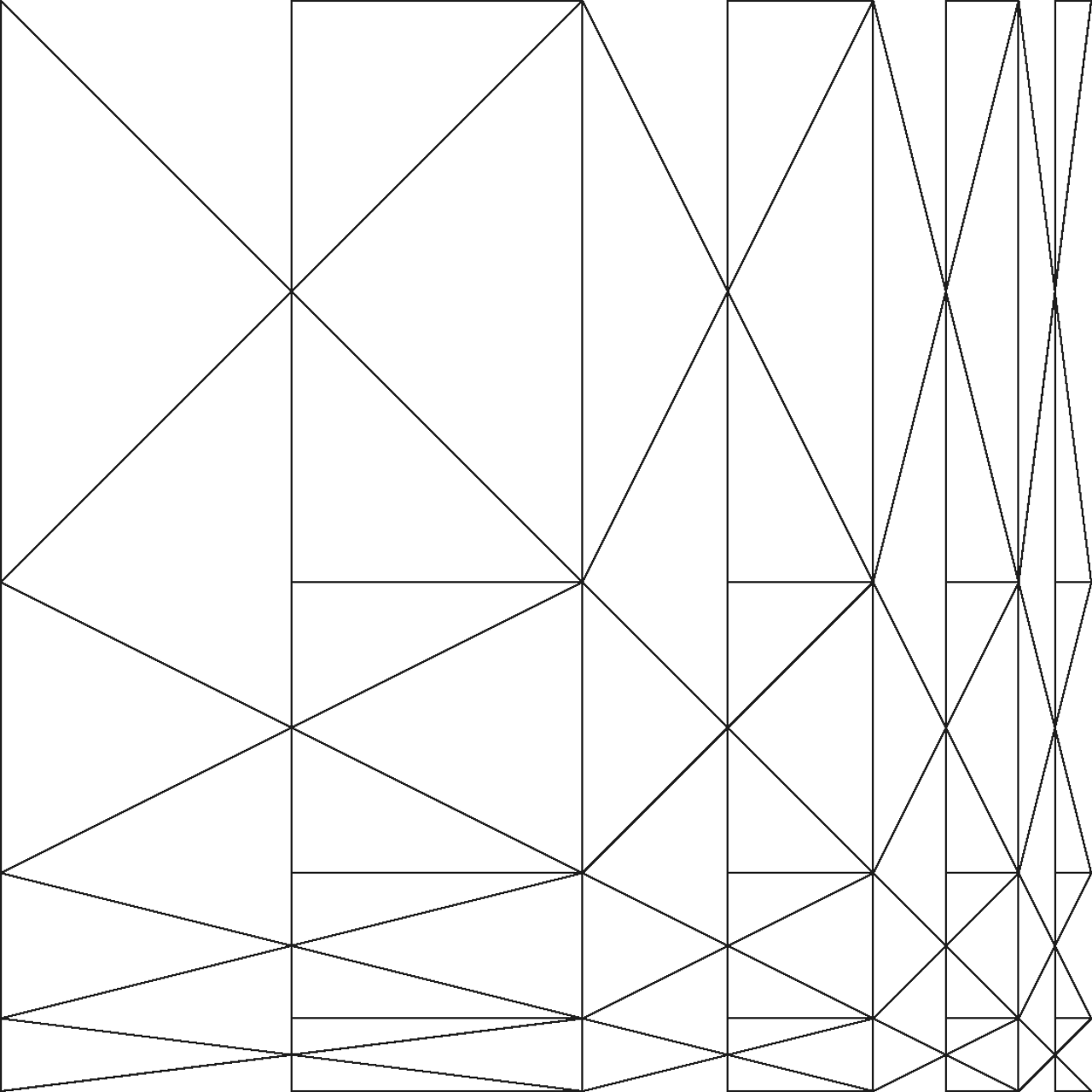

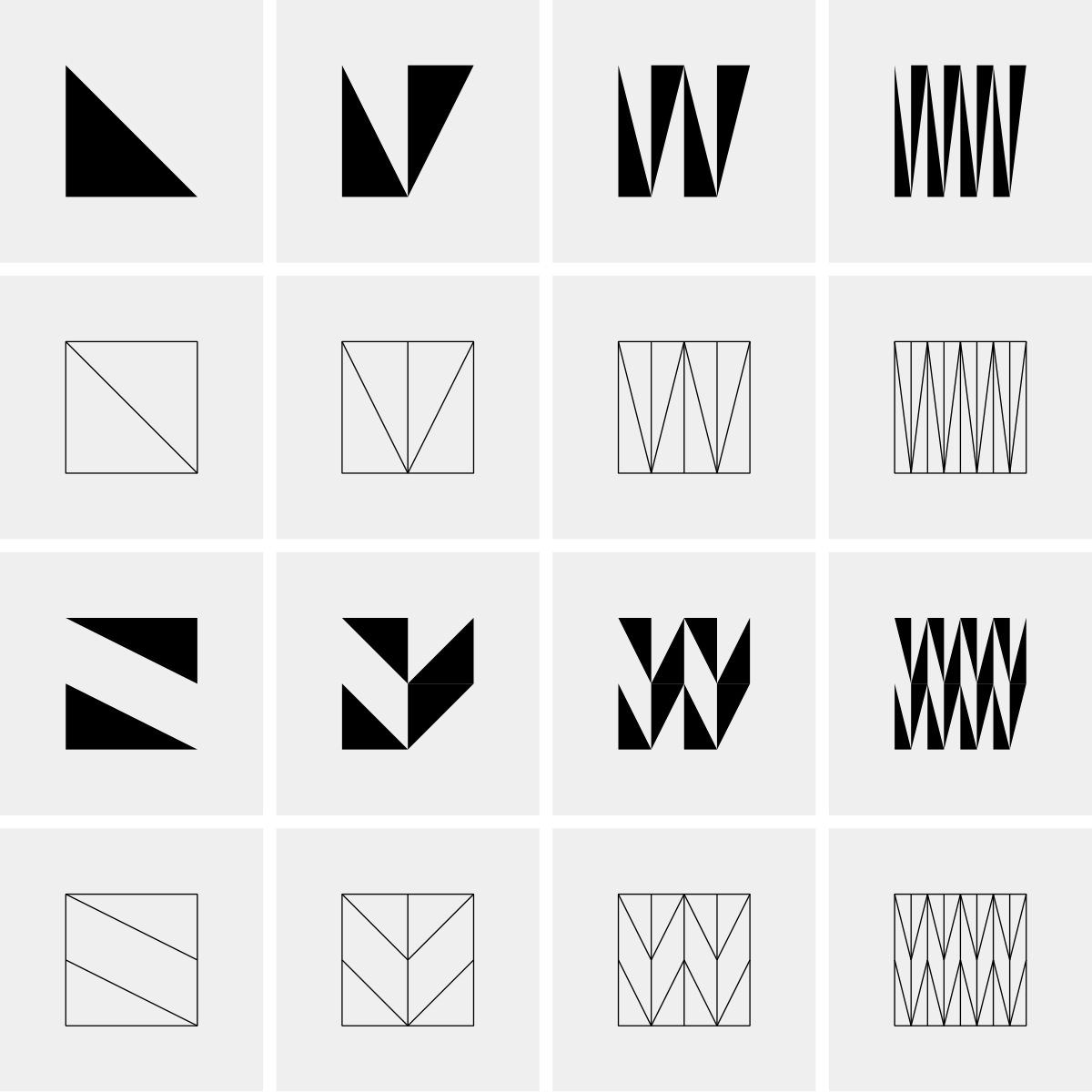

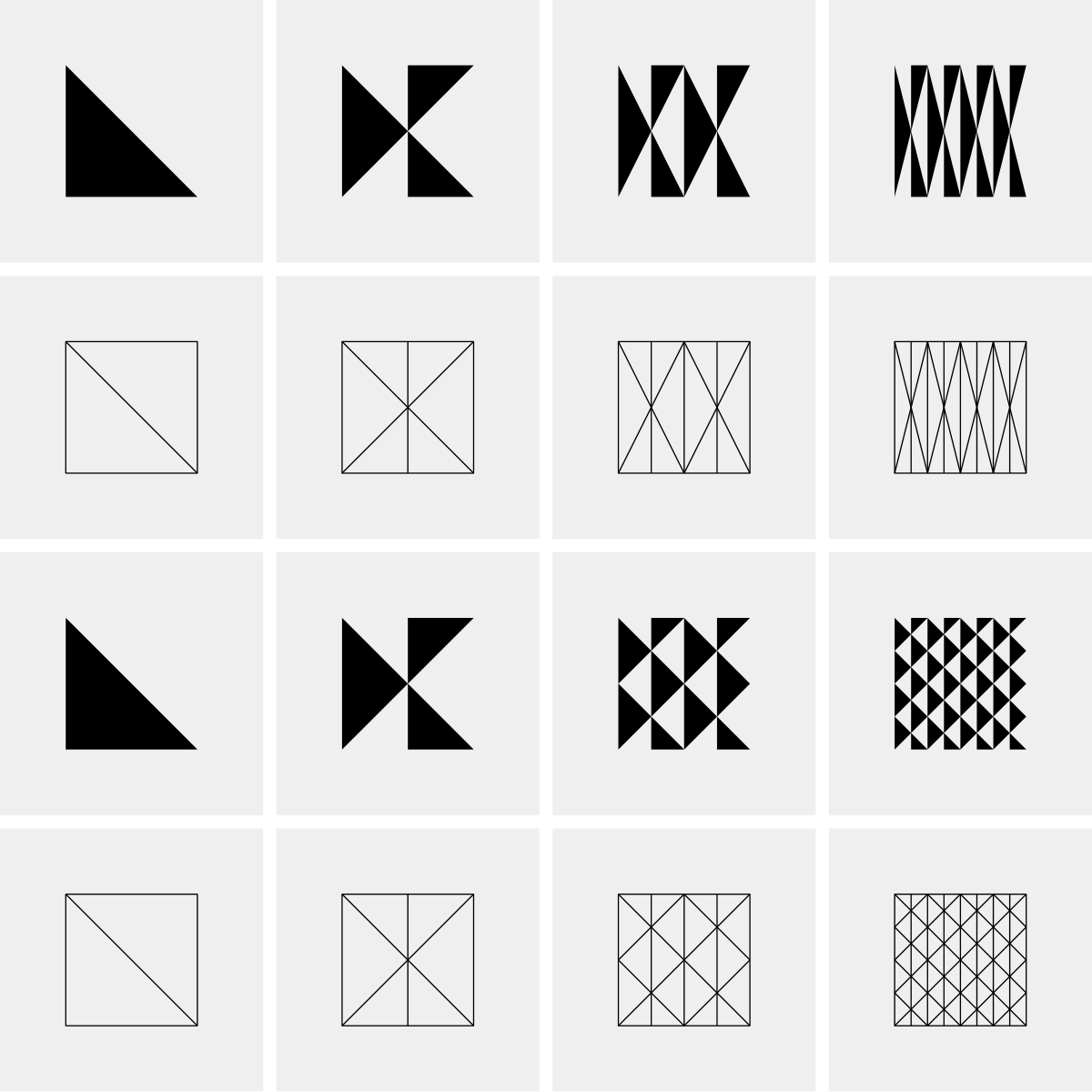

More precisely, Alexandra speaks the visual language of geometry and grids. She uses the potential of folding techniques and follows a meticulous principle of order. By combining simple principles, she transforms folding grids from 2D into 3D and creates multi-faceted jewellery.

We have all heard the term ‘facet’, but few can describe it accurately. The word itself derives from the Latin ‘facies’ (meaning ‘front side’ or ‘face’) and is basically nothing more than a flat or smooth surface on a geometrical shape. Thus, facets find their use in stone carving, dental technology, art and printing, or can even be found as part of a personality trait in psychology.

Our facets are created by folding techniques — more precisely, by the ‘X-Form’ grid. By adding or taking them away, different dynamics and structures are created that have a technical-minimalist or organic-floral appearance.

The caster we work with, Kalman Hafner, purchases ‘fair gold and silver’ from Fairever. To support workers dependent on small-scale mining, Fairever purchases gold and silver directly from responsible mines.

Fairever goal is to ensure the workers live a safe and healthy life as part of an intact society and environment. It is important to support local communities, especially small-scale producers, through Fairtrade and Fairmined certifications. Obtaining these certifications ensures that fair working conditions and equitable compensation are part of the supply chain.

With its commitment to Fairtrade and Fairmined, as well as sustainable mining practices, Fairever stands out by believing in the power of ethical jewellery to create a positive impact on communities and the environment.

Unlike recycled gold, sustainable or fair trade gold comes from mines that have certificates such as Fairtrade, FAIRMINED, or IRMA (Initiative for Responsible Mining Assurance).

Certification systems are particularly important for the small-scale mining group, ASM (Artisanal and Small-scale Mining). The aim is to protect against exploitative practices by multinational companies and threats from criminal gangs.

In addition, the establishment of ASMOs (Artisanal and Small-scale Mining Organizations) is encouraged to improve mining techniques and working conditions.

‘Fineness’ is a unit of measurement and indicates the ratio in which a valuable element is contained in a precious metal alloy.

As we learned in chapter ‘alloy’, fine gold is the name for pure gold, i.e. a metal that has an alloy with at least 99.9% gold. This alloy is commercially available as 999‰ fine gold and is rated at 24 karats.

As well as fine gold, fine silver is another material that creates the basis for high-quality jewellery. Fine silver is usually further processed as a component of alloys because, in its purest form, it is very soft and cannot be easily used as a base material for jewellery. Therefore, silver often occurs as sterling silver, a silver alloy with 93.5% or 92.5% fine silver content. The rest of this alloy is typically made up of copper.

The term ‘fine jewellery’ is used for all jewellery made from precious metals such as gold, silver, or platinum. Real gemstones such as diamonds, sapphires, rubies, or emeralds are usually used for fine jewellery.

In contrast, ‘costume’ or ‘fashion’ jewellery refers to any jewellery that is not made from precious metals. Fashion jewellery is sometimes referred to as ‘junk jewellery’ and is often made from cheap base metals such as brass, copper, or aluminium. It can also be made from textiles or leather, or base metals plated with precious metals. If a piece of fashion jewellery is decorated with a gemstone, it is almost always an imitation gemstone, i.e. the ‘gemstone’ can be made of plastic, glass, or crystal, among other things.

Fine jewellery is designed to last a lifetime and can even be passed down through generations. When fine jewellery breaks, it can usually be repaired. In addition, fine jewellery retains its value in the future.

The term ‘falten’ (to fold) is firmly anchored in our language — according to DWDS (Digitales Wörterbuch der deutschen Sprache), the Old German word ‘faldan’ first appeared around 800 AD and developed over the following centuries from ‘valten’, ‘valden’ to ‘vōlden’, and in the ninth-century from ‘faldōn’, ‘faltōn’ to finally ‘falten’. There were also various meanings in circulation, such as ‘to bend’, ‘to fold’, or ‘to bend over’.

‘Folding’ has multi-layered meanings and is in the truest sense a product of nature. In the course of our evolution, landscapes have folded, as well as leaves, flowers, buds, shells, snail shells, mushroom caps, insect wings, and much more. We ourselves carry it on our skin and even in our bodies as a helical double helix — DNA.

Scientists, engineers, mathematicians, educators, artists, designers, and hobbyists of all ages continue to be fascinated by folding. It is not just paper creasing but can be transferred from 1D to 2D to 3D and is independent of materials.

The German educator Friedrich Froebel recognised the potential early on and incorporated it into his ‘Spielegaben’. Josef Albers and Paul Jackson, for example, also used paper folding to teach their students an understanding of geometry, spatial thinking, or simply artistic expression.

Many remarkable inventions have emerged from science and technology that have found their inspiration in folding. For example, the airbag, or tiny origami robots that enter the stomach via a capsule and can be controlled from the outside when unfolded.

Friedrich Wilhelm August Froebel (* 21.4.1782 Oberweißbach in Thuringia, † 21.6.1852 Marienthal near Bad Liebenstein in Thuringia) simply has to be mentioned here because he saw the potential of simple geometric shapes over 170 years ago and incorporated them into his teaching methods.

Froebel was a German educationalist, pedagogue and vocational school teacher and is recognised as the inventor of the kindergarten. He developed the system of toys and activities (‘Spielgaben und Beschäftigungen’), which were simply referred to as ‘Froebel’s Toys’. These could be stacked, laid, moved, folded, cut, pulled, plaited, laced, woven, sewn, stitched, modelled or kneaded. Fröbel wanted to use ‘play’ to stimulate the child’s independence, dexterity, haptic experience, creativity, motor skills and capacity for abstraction.

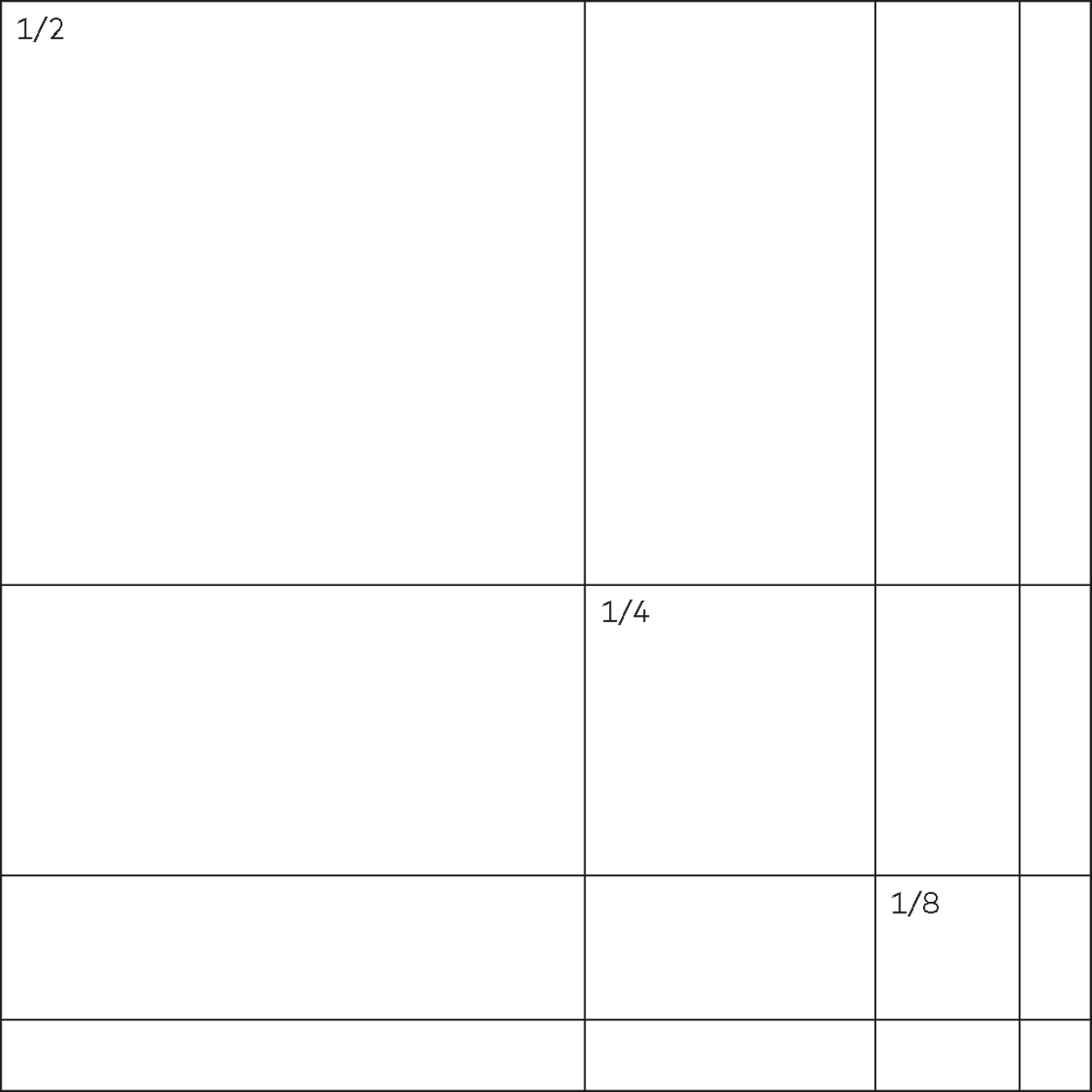

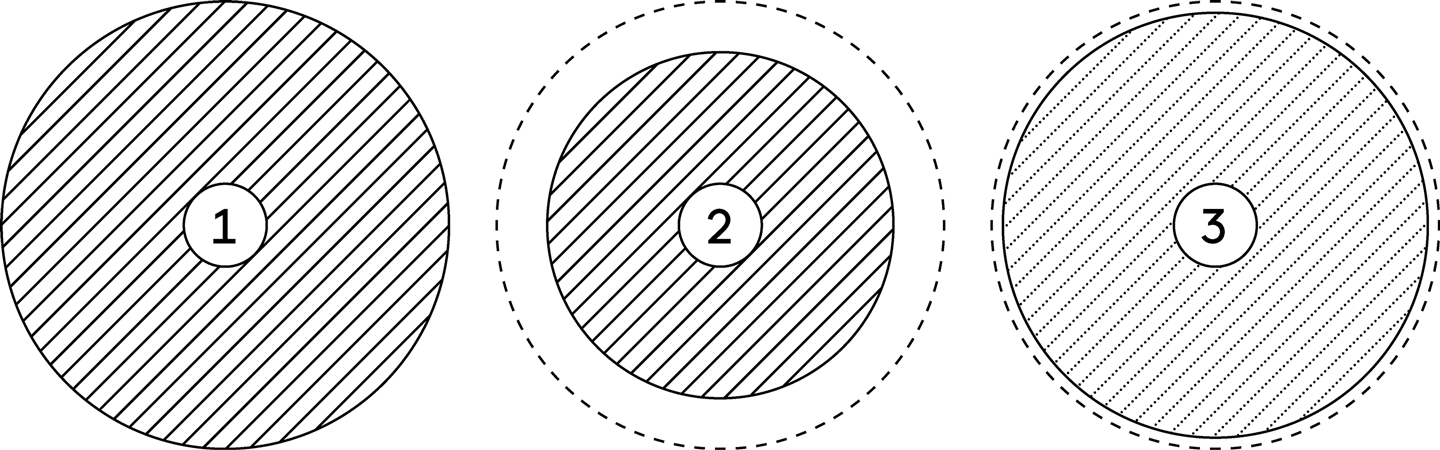

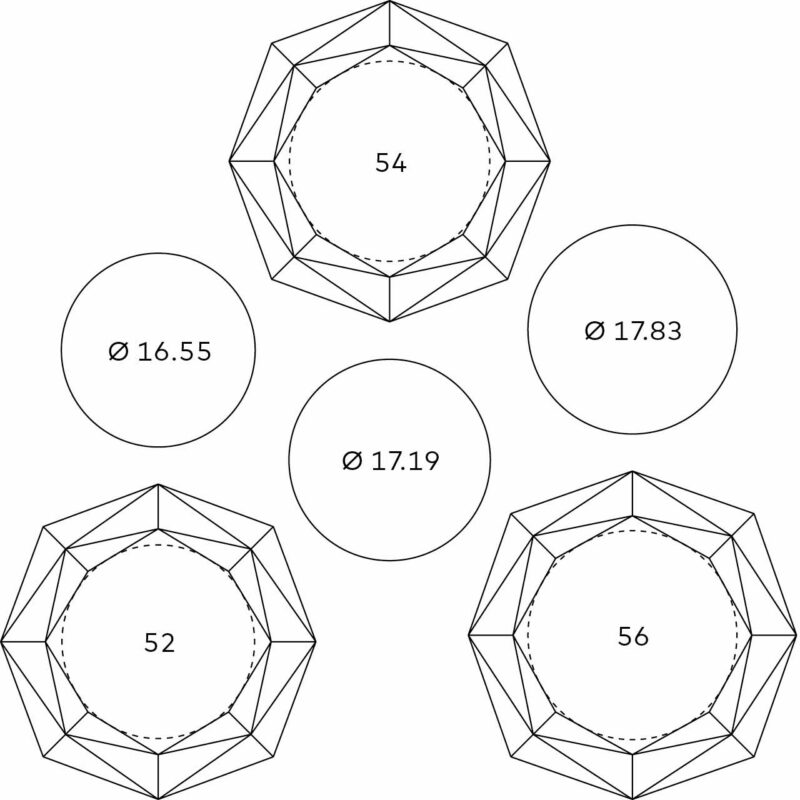

We use a mathematical number sequence — in our case the Geometric Series — as a useful tool. To limit and control the folds, we take the approach of doubling (1, 2, 4, 8, etc.) and halving (1, 1/2, 1/4, 1/8, etc.), both in the number of facets and dimensions.

Four of our six categories strictly follow the rule. However, since rings and bangles correspond to natural body measurements, they are each drawn and adapted separately.

This refers to the embossed or stamped symbol in a precious metal that provides information about its fineness.

In Germany, the most common stamps are 333, 585 and 750 for gold, 835 and 925 for silver and 950 for platinum. These are not mandatory, but the legal text states that the fineness must be indicated with whole number thousandths, (§2 Para.1, §3, §5 Para.1 FeinGehG).

Legal regulations on hallmarking vary from country to country. England, for example, has been using and controlling hallmarks for over 700 years, and counterfeiting is still punishable by law.

Hermann Gloeckner (* January 21, 1889 in Cotta near Dresden; † May 10, 1987 in Berlin) was a German constructivist painter, sculptor, artist and graphic artist. Over five decades, the theme of folding was a constant companion, creating works in one-, two- and three-dimensional form.

Josef Albers (* March 19, 1888 in Bottrop; † March 25, 1976 in New Haven, Connecticut) was a German-American painter, art theorist and educator. His most famous work is probably his colour square painting ‘Homage to the Square’, which is one of the pioneers of Op Art, optical art.

In addition to his studies on colour theory, Albers also devoted himself to the subject of folding. As early as the 1920s, Josef Albers taught folding techniques at the Bauhaus in order to provide his students with solutions to problems. He encouraged students to plan their folded paper models in advance to ensure that the economy of form was in proportion to the expected amount of material and labour.

Kalman Hafner is our partner with over 55 years of experience in investment casting. The caster offers productions ranging from individual pieces to series, which are realised in complex work steps using the so-called lost-wax process.

Kalman Hafner purchases certified and recycled precious metals from nearby refineries in and around Pforzheim, such as:

Bauer Walser AG →

C. Hafner GmbH + Co. KG →

Agosi AG →

An additional partner for certified ‘fair gold’ is Fairever.

Casting is a craft that has been used for thousands of years and became possible with the development of brick kilns around 3000 BC. Various processes have developed since then, such as centrifugal casting, die casting, continuous casting, mould casting, to name a few.

Our partner Kalman Hafner is specialised in investment casting, and brings our jewellery to life using the so-called ‘lost-wax process’. In this process, a duplicate is cast from an original in several complex steps:

The finished raw casting is then sent for quality control and, if accepted, to the goldsmith. The goldsmith cleans the model so that the finished master serves as a template for duplicates.

We enjoy working with casters, goldsmiths and metal suppliers from Pforzheim, where everyone is local and well-connected. FP believes in supporting local craftsmanship and want to maintain long-term relationships with the manufacturers and workers.

If you would like to get in touch with us, please feel free to do so. We have already gained in-depth knowledge and experience in the industry and are happy to share our expertise with goldsmiths, designers or simply jewellery lovers.

Since 1983, Paul Jackson has been a professional paper folder, paper artist, paper engineer, author, and teacher specialising in origami and the art of folding. In addition, he ventures into other worlds and explores folds in pedagogy, mathematics, physics, music, and of course nature.

Paul Jackson has written over 40 books and taught students in design fields such as architecture, fashion, ceramics, jewellery, product design, and textiles at more than 80 universities and colleges in 13 countries.

Together with his wife, Israeli origami artist and educator Miri Golan, he founded the ‘Folding Together’ project and launched the ‘Origametria’ program, which uses origami to teach geometry. Since 2018, it has been included in the national mathematics curriculum by the Israeli Ministry of Education.

Today, more than 30,000 primary school-aged children learn origami every week to strengthen self-esteem, but also to develop motor skills, hand-eye coordination, logical thinking, concentration, aesthetics, three-dimensional perception, and the basics of geometry.

Pforzheim — formally ‘Portus an der Enz’, a Roman settlement founded in 90 BC — is a large city in the Black Forest with a long history for goldsmiths, jewellery artists, designers, and jewellery lovers. With over 250 years of jewellery and watch traditions, Pforzheim remains a Mecca for all things jewellery-related still to this day.

Additionally, it is still home to a number of jewellery-related exhibitions and cultural centres, such as:

Technisches Museum der Pforzheimer Schmuck- & Uhrenindustrie →

The three most common precious metals in jewellery processing are gold, silver, and, in recent years, platinum, but there are plenty more. Precious metals are rare and are mined under more difficult conditions, compared to sand, for example.

The special thing about these precious metals is that they are corrosion-resistant, meaning they hardly react to air or water. In ancient times, coins were usually made of gold or silver because they had a certain quality standard and were valuable. However, it occasionally happened that fraudsters filed gold off the edge of the coins and thereby enriched themselves. To stop these gold thieves, the fluted edge that we still know today was created.

A few facts about gold and silver mining — the largest producing countries in terms of gold reserves are China, Australia, Russia, and North America (USA and Canada). The leading countries in silver mining are Mexico, China, Peru, Chile, and Australia.

It currently takes several weeks to produce small quantities of our jewellery. This is because there are various complex processes going on behind the scenes.

But let’s start from the beginning. After examination folding techniques, basic ideas are drawn, finalised and 3D printed. After reviewing the prototypes and making any necessary adjustments, the CAD drawings are reviewed for feasibility. Once the design process is complete, the actual production takes place in five steps:

1. CAD works & 3D printing

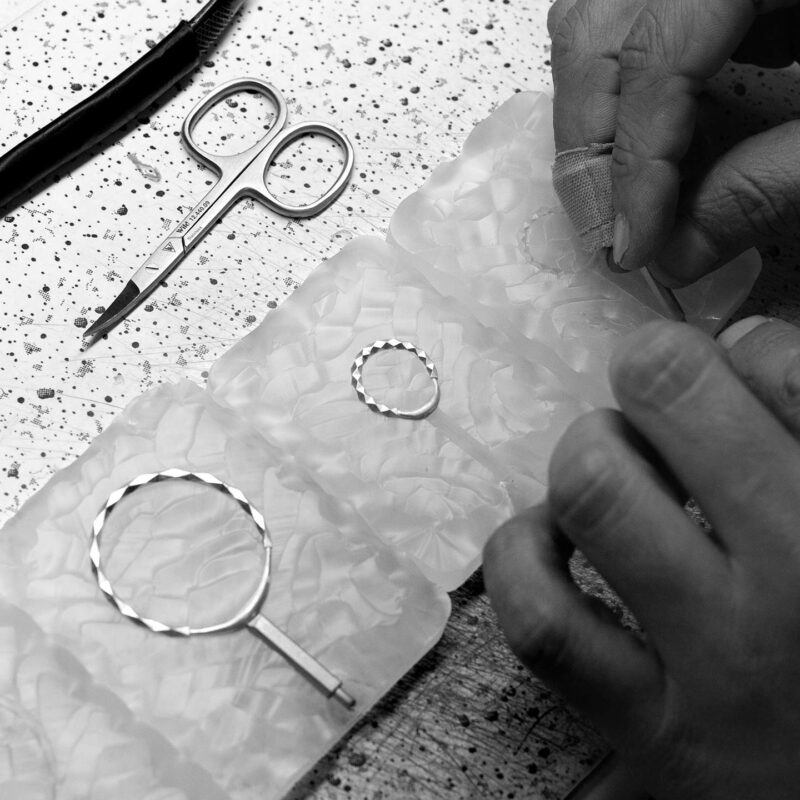

Based on the CAD design, a model template is created, which is used to produce the final form. After plotting the file, the piece is handed over to the goldsmith, who trims and cleans the surfaces carefully by hand.

2. Moulding

After cleaning, a rubber or silicone mould is made. With this mould, all parts will be cast in the desired alloy in the future. To ensure a consistently high quality, the most modern wax spraying machines are used for production.

3. Lost-wax process

From a single piece to small quantities, the jewellery is cast with most modern vacuum casting machines in the selected alloy such as recycled silver, gold, or platinum — everything with more than five decades of casting experience.

4. Goldsmith works

Once the pieces have been cast, they are cleaned by hand and prepared for wearing. This includes, for example, soldering in ear-studs or attaching eyelets for chains. Afterward, the pieces are sandblasted to give them a matte finish.

5. Plating & quality control

The final step is the (galvanic) plating in the desired colour and thickness. The plating on our rings is thicker since they are more likely to come into contact with other objects. After a final quality check, your jewellery is then ready for delivery.

All this is done only by wonderful professionals who help transform ideas into concrete jewellery and bring them to life. Thank you!

REACH is the European Union’s Regulation (EC) No. 1907/2006 and stands for Registration, Evaluation, Authorization and Restriction of Chemicals.

The focus is on protecting human health and the environment from the risks posed by the use of chemicals. At the same time, it aims to improve the competitiveness of the chemical industry in the EU and promote alternative methods for harmful substances in order to reduce testing on animals.

Basically, there are two main differences between recycled and fair-trade precious metals — one is recycled, and the other comes from the ground.

Recycled gold or silver, for example, are obtained from the recovery of already processed metal from old jewellery, watches, coins, objects, and even electronic waste. After disassembly, the collected material is cleaned and melted together so that it can be put back into circulation as recycled gold and recycled silver.

Even if the precious metals are recycled, this is not 100% the case. Recycled silver consists of around 95% recycled material, gold in some cases only around 30%. This means that the rest is still mined and mixed in.

Another point in addition to using resources sparingly is reducing our ecological footprint. When recovering, cleaning and processing recycled gold, CO₂ emissions are significantly lower than the actual extraction of gold in mines. This is what the eco-balance of the NaGold project at the Pforzheim Institute for Industrial Ecology revealed: with around ten to 20 tonnes of CO₂ per kilogram of mine gold, recycled gold from high-quality electronic scrap performs surprisingly well with 53 kilograms of CO₂ per kilogram.

RJC (Responsible Jewellery Council) was founded in 2005 and is a leading global standards-setting organisation for the global jewellery and watch industry to promote sustainable supply processes.

RJC is the only ISEAL member for sustainable standards and practices in the jewellery industry. The code of conduct is based on the 17 SDGs (Sustainable Development Goals), and the ten principles of the UN Global Compact.

RJC CoC (Chain of Custody Standard) provides full transparency of traceable and responsibly sourced practices. The certification contains information on how products and their materials have been sourced, traced, and processed in the supply chain.

Furthermore, the CoC ensures that the procurement of the semi-finished products manufactured by RJC, LBMA (The Independent Precious Metals Authority), or RMI (Responsible Minerals Initiative) certified refineries is conflict-free.

RJC CoP (Code of Practices Standard) enables practices focussing on ethical, social, human rights and environmental requirements. CoP helps to measure practical action tasks, and is the only one that covers the entire supply chain of the jewellery and watchmaking industry.

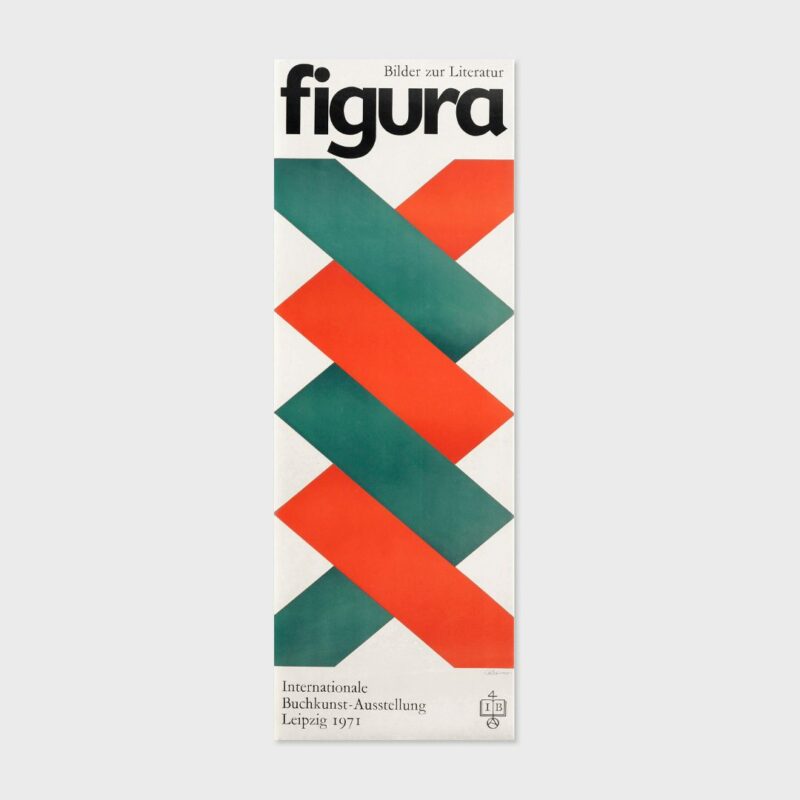

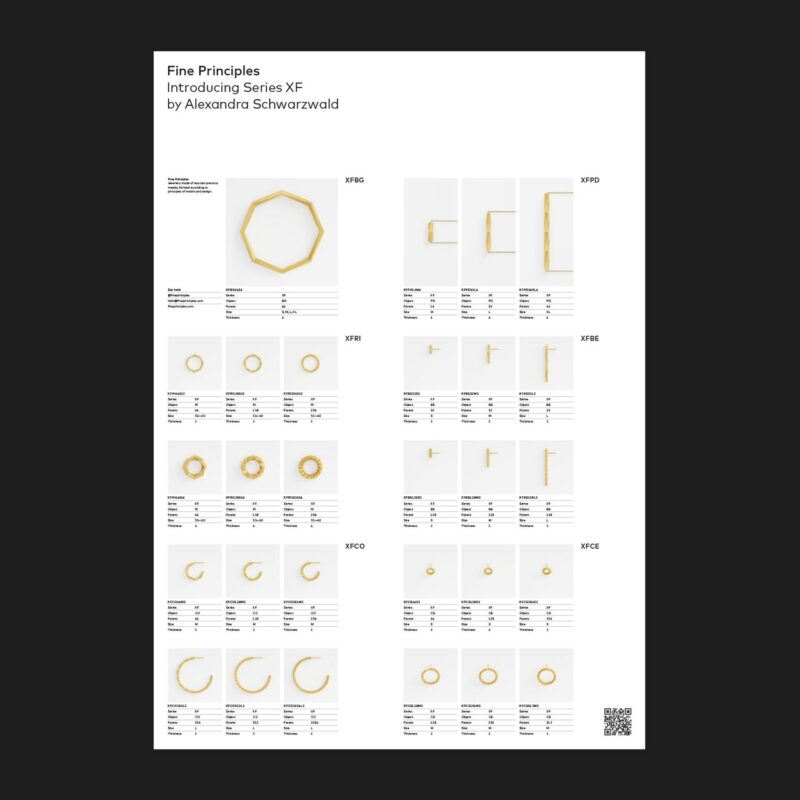

‘Series XF’ is our first collection and is inspired by the ‘X-form’ folding technique. As the name suggests, the shape consists of a repeating pattern of triangles that resemble consecutive Xs.

The entire collection consists of 28 pieces and is divided into six categories — ring, bar earring, circle earring, bangle, pendant, and creole. The jewellery follows a timeless approach and is made for everyone.

We love the aesthetics of sharp edges, and we hope you do too. To maintain this particular feature, we leave the surface as pure as possible after casting. Accordingly, all our pieces have a slightly textured but shiny surface.

Just a quick reminder — A piece of jewellery can be worn every day, which means that plated rings and bracelets, in particular, can wear off more quickly than earrings. It is completely normal as they automatically come into contact with other objects. Hence, we offer a touch-up service in which the goldsmith cleans the surface, and plates your piece again.

Ask for the touch up →

Our sustainability approach starts with the product, which is made from certified and recycled precious metals. Both the caster and the goldsmith work with local suppliers who are certified or authorised members of the RJC, Fairtrade and Fairmined, and comply with REACH regulations. Additional jewellery accessories, such as ear pins or chains, are also made from certified precious metals and purchased locally from Berlin.

Furthermore, the jewellery boxes are made of FSC®-certified MDF wood fibreboard covered with FSC®-certified black Soft Touch paper. They are shipped in FSC®-certified kraft cardboard. Additional marketing materials are made from 100% recyclable, compostable or FSC®/PEFC™-certified paper and is only produced in small quantities in Germany.

Sustainability within a company is much more complex than just looking at products or packaging. Many of us within the industry are already on the right track, but more can always be done. At Fine Principles, we will always work on continuing to improve our own internal standards — it’s a work in progress!

We like to use the word ‘transformation’ because it describes the remodelling of 2D grids into 3D objects. Imagine a flat sheet of paper that transforms into a bird, for example, during folding. In this case, we do the exact same thing, only digitally.

We believe that our jewellery is suitable for everyone. Based on a systematic approach, everyone can simply combine the pieces as they wish, be it by size, model, or colour. Have fun mixing and matching!

Nowadays, it is more important than ever to think about the responsibility and conservation of our natural resources. Part of a strategically circular economy is ‘urban mining’, which aims to take into account all material flows from raw material extraction to waste management and to reuse the secondary materials obtained.

‘Urban mining’ is also used in metal processing by German refineries to recover secondary metals. Precious metals from e-waste, for example, are recycled and processed into secondary materials that are integrated into the circular economy.

With the help of ‘urban mining’, a more responsible approach is to be anchored in the jewellery and watch industry. This is because the mining of gold and silver is still an environmentally harmful and social problem that is associated with a wide variety of conflicts. An ethical standard along the entire value chain is therefore essential for both producers and consumers.

XF is derived from the folding technique ‘X-Form’. As the name suggests, the X-shape consists of a repeating pattern of triangles that resemble successive Xs. Today, we find ‘X-Form’ in paper folding, of course, but also in sculpture, art, architecture, ceramics, graphics, and jewellery design.

3D technology has long been an integral part of the jewellery industry. Among others, it consists of software that can be used to draw 3D models and hardware that can be used to print 3D models.

For us, 3D modelling gives us the freedom to create more complex and complicated geometries than possible by hand. In fact, Alexandra started out that way, but then deliberately switched to 3D modelling in order to explore the world of digital folding more efficiently.

With 3D technology, we can make customer-specific adjustments more quickly and produce in small series. All of this is done with the help of local workshops in Pforzheim, who implement our designs using 3D printing along with handcrafted methods.